15 catamaran type vessels are being built at Özata Tersanecilik’s shipyard in Yalova for Izmir Metropolitan Municipality, which aims to transport passengers in the Gulf of Izmir with fast and comfortable ships produced with the latest technology. The hulls of the ships are produced from carbon composite material, which is shown as the technology of the future. Industry representatives consider the choice of carbon composite material for vessels as an important decision for Turkish maritime to serve the world in a new segment. The first ship hull manufacturing, planned to be delivered approximately 6 months later, has been completed.

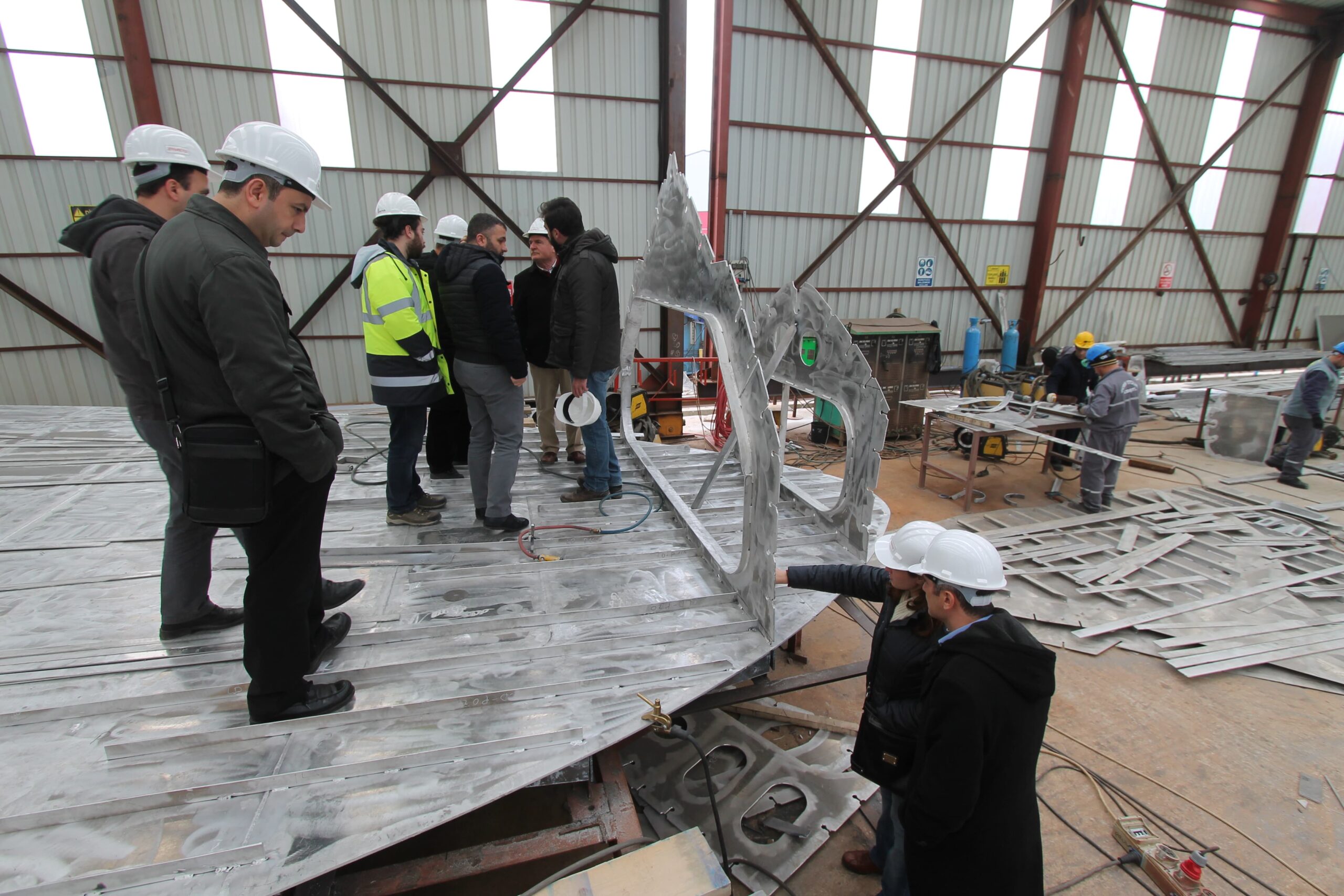

Izmir Metropolitan Municipality Mayor Aziz Kocaoğlu, together with representatives of the maritime industry and members of the press from Izmir, went to Yalova and examined the vessel, the hull of which was completed at Özata Shipyards, where production took place.

Noting that Turkish shipping has taken a big step with the manufacturing of these vessels, Kocaoğlu said: “We could not find a contractor company when we initially went out to tender. Then Mr. Özdemir made an offer. With the manufacturing of these vessels, Turkish shipyard industry will experience a great leap forward. We will definitely bring our country to the place it deserves by creating added value and saving money. This investment is not just about 15 vessels, it has aspects that will open the horizon for the sector. “I hope our vessels will add colour to the Gulf as soon as possible,” he said.

Özata Shipyards Chairman of the Board of Directors, Özdemir Ataseven, said that the largest passenger vessels in the world, made with carbon composite material used in aviation and space technology, were produced for Izmir. Ataseven stated that this investment of the municipality enabled the world maritime industry to turn its attention to Yalova and said, “The vessels aroused interest worldwide. We observed first hand that the most interesting product at the world’s largest maritime fair held in Norway last month was the catamaran ships we are building. “I would like to thank everyone who contributed to the creation of the project, especially the Mayor of Izmir Metropolitan Municipality, who opened this path for us,” he said. Ataseven said that Azerbaijani investors also came to Yalova to examine carbon-composite technology for their new vessels.

Underlining that they started project planning in coordination with Izmir Metropolitan Municipality after the contract was signed in June 2012, Ataseven continued as follows: “We started to work jointly to build environmentally friendly ships that are beautiful, comfortable and have the expected technical capacity, befitting Izmir. We designed a beautiful ship with modern lines. The model we produced successfully passed the tests in a laboratory specialized in catamaran boats in Poland. We have also initiated investments to make the infrastructure of our shipyard suitable for carbon composite production. We have sanctioned $9 million so far. We will invest this much more until the end of the project.” Domestic manufacturers will also be included in the project. Emphasizing that the decision made by Izmir Metropolitan Municipality regarding the purchase of carbon composite catamaran ships is of historical importance for Turkish maritime, Ataseven said, “The municipality’s order is one of the most important and accurate decisions for Turkish maritime to serve the world in a new segment. As the main contractor of the project, we see the inclusion of domestic producers in this project as one of our main duties. And we are working together with the Localization Commission of the Chamber of Naval Engineers and the Ship Industrialists Association on this issue. The design and production control of the ships was carried out by Norway Loydu DNV, a classification society that stands out with its experience in the world. We proceeded according to the deadline plan they prepared at the beginning of the project. We will put the ships at the service of the people of Izmir without any delay,” he said.

Received Full Marks From Sailors

Chamber of Shipping Izmir Branch Council President Geza Dologh: We are very happy to see the first ship. We saw an example 2 years ago. These ships were decided 13 months ago. And the first baby is ready to be born. Hopefully he will be born at the end of the year. Then the ships will be born one after the other every 3 months. We liked it very much. I think there won’t be a problem. In fact, it is a new technology that will be very beneficial to the Turkish ship industry. “Izmir Municipality will be an example,” he said.

Chairman of the Board of Directors of the Chamber of Shipping Izmir Branch Yusuf Öztürk: This is a product of Turkish workers, engineers and shipyards. As a native of Izmir, I felt really proud. We went in and walked around. I think it will suit Izmir and our municipality very well. It is also produced from a very suitable material. The advantages of being light are many, and fuel consumption is also very low. Fast. I think we will travel very comfortably in the inner and outer bays.

Chamber of Naval Engineers Izmir Branch President Emrah Erginer: We wish you the best of luck. We had previously prepared and submitted a report on this issue to the municipality, and we had also made statements. Hopefully, the project will be completed and finished successfully from now on. I hope they will be successful and all will be delivered on time, he said.