The uncertainty caused by the contraction in the shipbuilding sector along with the effects of the global crisis also affected Özata Shipyard. However, winning the Izmir Passenger Ferries construction tender boosted morale.

During the crisis that has been ongoing in the maritime industry since 2008, Özata Shipyard was one of the shipyards that turned to “special vessel construction” projects.

Özata Shipyard, which is currently operating at 30 percent capacity on a 50-decare land in Yalova, continues on its way with new projects undertaken at home and abroad, in addition to undertaking the tender of Izmir Metropolitan Municipality for the construction of 15 passenger vessels to be built with “carbon composite” technology last year.

Stating that they received the construction work of two domestic passenger vessels during the crisis, Özata Shipyard Chairman Özdemir Ataseven said, “We cannot say that we did not receive work during the crisis. We went through the crisis period a little more fortunately, thanks to the projects we signed at the beginning of this process. During this period, we continued the construction of two chemical tankers, one of which is steel construction and the other is turnkey. During this period, we completed the construction of four pontoons to be used in the Caspian Sea. These projects sustained us in the first phase of the crisis, that is, for a year or two. Meanwhile, we also received projects from abroad. For example, we received a large business from Ukraine. We also received a passenger vessel construction job from Azerbaijan. When we look at it, we see that we have received good work. Of course, we also experienced great difficulties during this period. “Building a few vessels will not solve the crisis,” he said.

SHIPYARDS SHOULD DIRECT TO CONSTRUCTION OF “SPECIALTY SHIP”

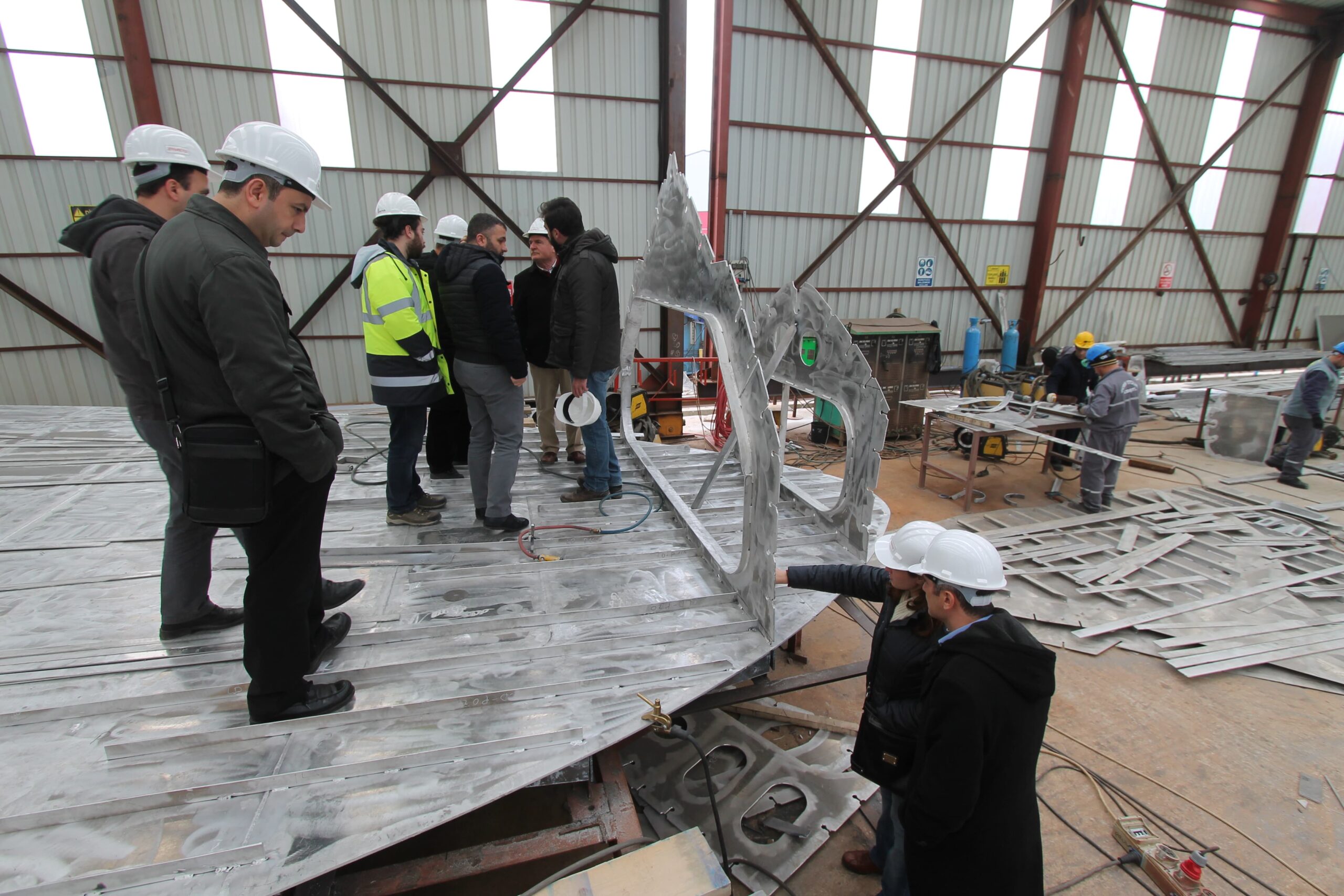

Ataseven stated that shipbuilding cannot progress only by building tankers, dry cargo ships or containers, and emphasized that Turkish shipyards should focus on specific shipbuilding and special projects in addition to these projects. Citing “carbon composite technology” as an example in this regard, Ataseven said, “The project of 15 carbon-hulled catamaran type sea buses to be built for the Izmir Metropolitan Municipality, which can be considered a big step in our plan to realize the ‘special vessel’ construction that we targeted as Özata Shipyard in the recent past, has started. The ships will be built from carbon composite. “13 of these will be used for in-port voyages, and 2 of them will be used for out-of-port voyages,” he said.

Özdemir Ataseven describes carbon composite technology, which is mostly used in aviation and space technology and nuclear power plants, as the technology of the future. Stating that the most important feature of this technology is that it is very light, Ataseven said, “We are building passanger vessel with the same features as the passenger vessel we are currently building, from the usual materials of steel and aluminum, but the weight of these ships is 450 tons. The weight of the vessels we built with carbon composite technology is 130 tons. Naturally, the reduction in weight greatly reduces fuel consumption. This creates a huge advantage for the operator in the long term. Due to this great reduction in fuel consumption, vessels built with carbon composite technology pay for themselves in a short time. Repair and maintenance is also very easy. Most importantly, they are environmentally friendly vessels. This material has a familiarity with sea water. It does not absorb sea water like sheet metal and melt it. In other words, it has a positive relationship with sea water and has no life limit. “As the name suggests, they are greenship vessels,” he said.

CARBON COMPOSITE VESSELS WILL SAVE FUEL

Stating that Norway is currently dominant in this technology in the sector, Ataseven noted that the carbon composite passenger vessel project and ferries are in the first place at Özata Shipyard. Ataseven stated that they aim to further develop car and passenger transportation in the coming period and said, “Carbon composite technology provides profit to the operator in terms of fuel consumption in passenger vessels and passenger transportation. It is also very advantageous in terms of repair and maintenance. There is the opportunity to intervene immediately. This technology is a project that I am currently focusing on and see as the project of the future. There are only a few companies in the world that use this technology in shipbuilding. These companies are shipyards that have now become brands. A very large Norwegian company met with us before the Izmir tender. Meetings were held. “When they said, ‘Let’s carry out this work jointly, but let’s keep our name,’ the day we were going to enter the tender, I gave up entering the tender with them,” he said.

Stating that the entire sector supports and follows passenger vessel projects to be built with carbon composite technology, Ataseven stated that, as Özata Shipyard, they are trying to make the project 70 percent domestic.

GENERAL APPEARANCE OF SHIPYARDS IS BAD

Özdemir Ataseven, who also evaluated the situation of shipyards in Turkey, said that the general outlook is bad. Ataseven continued his words as follows: “The situation is almost the same in the shipyards in Yalova. Only difference; Repair and maintenance work continues. The situation of the shipyards that build military ships in Yalova is somewhat good. Repair and maintenance works keep these shipyards afloat. The slightly stronger shipyards are in a position to build and sell ships themselves. So, we can say that a few shipyards with bank support are working.”

Ataseven pointed out that direct support could not be given to shipyards during the process of joining the European Union, but support was given in the construction of military ships and said, “However, currently, the number of shipyards producing military ships is only five. We cannot spread this to the general public. In my opinion, the Defense industry should generally determine the criteria it wants, and every shipyard that meets these conditions and can prove that it can produce at the requested quality should have the chance to bid for such projects. I think that our Minister of National Defense, Mr. İsmet Yılmaz, is also working positively on this issue. We know that Mr. İsmet Yılmaz, when he was the undersecretary of maritime and when the Justice and Development Party was in power, implemented major projects in maritime, despite all the difficulties, and signed legislation that would pave the way for Turkish Maritime. Therefore, we believe that it will complete the regulations that will provide equal opportunities to all shipyards.”

Özdemir Ataseven stated that the government provided all support for maritime institutions to meet their needs by holding tenders and said that these developments provided a breeze to the stagnant atmosphere of the maritime sector. Ataseven added that institutions planning their needs in the future and using this support from the government to start projects that will stimulate the shipbuilding sector will increase the positive momentum of the sector.