The Chairman of Özata Shipyard, Özdemir Ataseven, states, “We will deliver a passenger vessel every 3 months until 2017. This production speed is not present even among our competitors in Europe.”

Özata Shipyard operates on a 55,000 square meter area in the Yalova Shipyards Zone. The shipyard, which started production in 2013, established one of Europe’s leading composite production factories for its 15 carbon catamaran projects. Özdemir Ataseven, the Chairman of Özata Shipyard, aims to achieve the goal of delivering a passenger vessel every 3 months by 2017 with its factories and hangars.

Within the project conducted in collaboration with İzmir Metropolitan Municipality, six vessels have been delivered so far. Ataseven states, “This production speed is not present even among our competitors in Europe.” Also serving as the Vice President of the Vessel Industrialists Association (GESAD), Ataseven mentioned that GESAD has established the Vessel Specialized Organized Industrial Zone in Yalova, a first in Turkey.

Can you provide information about Özata Shipyard? What types of vessels do you mainly construct? Can we get details about your technical capacity and workforce?

Özata Shipyard was established on an area of 55,000 square meters. Currently, steel, aluminium and composite hulled vessels and yachts are being built in a 7000 square meter closed production area. Especially recently, we have been focusing on carbon composite production, which I believe will be widely used in vessel constructions of the future. We think that this product segment will have an important share in the future of our shipyard. Our shipyard has made appropriate infrastructure investments for the realization of the 15 carbon catamaran projects that it started production in 2013 and, as we can proudly say, has established Europe’s leading composite production factory. We will deliver a passenger vessel every 3 months in these factories and special assembly hangars until 2017. This production speed is not even found among our competitors in Europe. There are currently 250 people working in our company. Depending on our intensity in projects, the number of our employees can reach up to 800 people.

What are the projects you are carrying out as Özata Shipyard? What can you say about the passenger vessel project for Izmir Municipality? What is the condition of the passenger vessel that Istanbul Municipality will put out to tender?

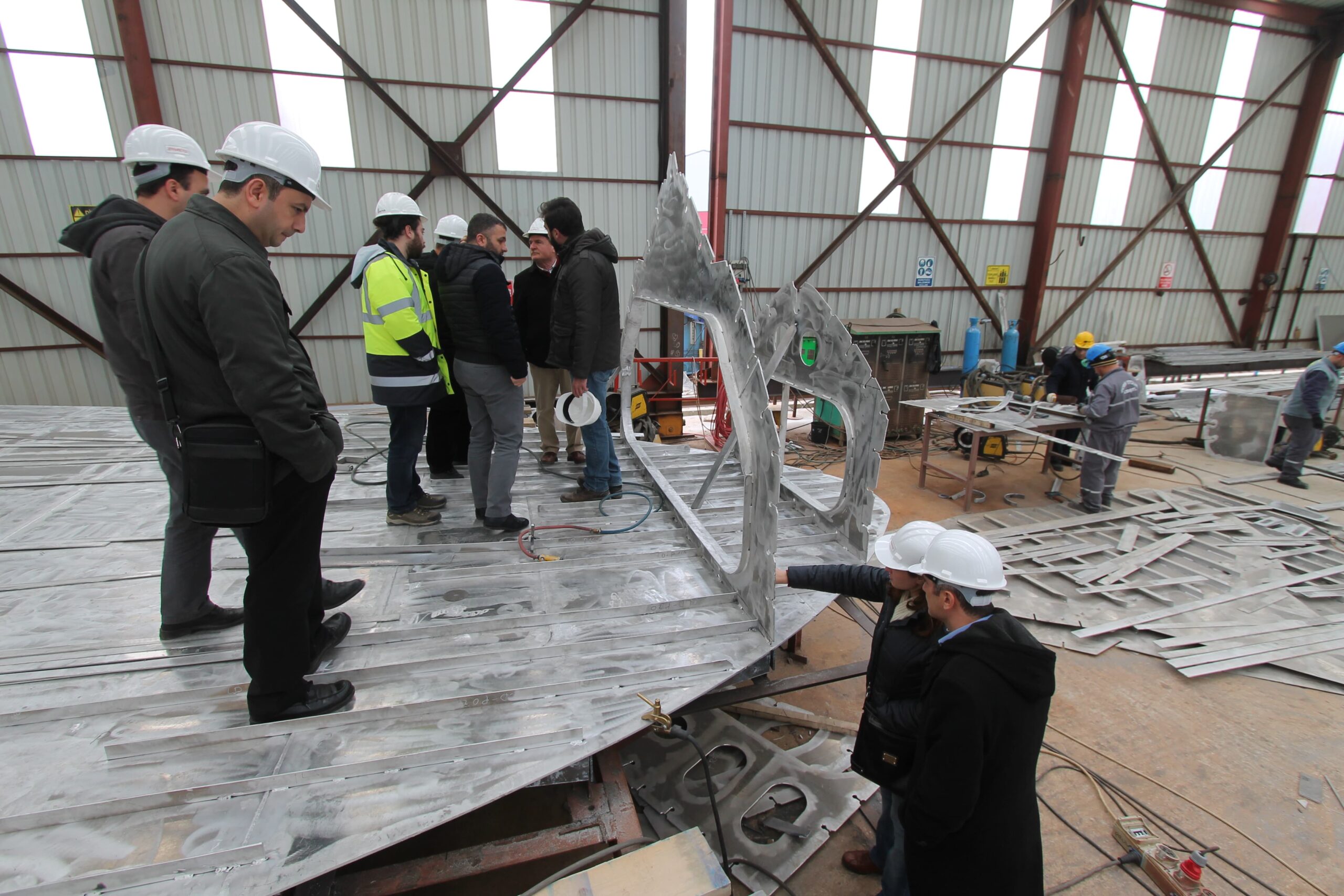

One of the projects we carry out as Özata Shipyard is the 15 carbon composite hulled catamaran passenger vessels being built for Izmir Metropolitan Municipality.

The feature of this project is the material of its body. The hull material was the material generally used in yacht production around the world. To talk a little about the technical features of the project; Carbon catamaran passenger vessels will be at a service speed of 18 knots, 2 of them will be at a service speed of 30 knots, and each passenger vessel will be equipped to serve 426 passengers. Passenger vessels will also be equipped with systems that can be easily used by disabled citizens.

Three of the Izmir passenger vessels are still under construction. Our vessels are delivered one by one. It will be completed within the promised agreement date and delivered to Izmir Metropolitan Municipality.

Istanbul Metropolitan Municipality recently held a tender. A tender was opened for passenger vessels which we call double and lended style and we were among the companies that submitted the best and lowest bids in this tender and by winning this tender. We started to produce ferries with a capacity of 700 people for the Istanbul Metropolitan Municipality.

It is said that the construction of offshore platforms will mark the coming years. What should be done for Turkey to get a larger share from this sector?

Now, naturally, we see an acceleration in the use of resources all over the world, especially in the last decade, and we also expect an increase in the construction of offshore platforms. In order for Turkey to get a larger share from this sector, first of all, references related to these platforms must be created in Turkey in some way. Therefore, there should be a successful reference project at least in one of the shipyards in Turkey regarding the construction of such platforms in our country, which have already been repaired, and I think Turkey can get a share from this project.

How do you evaluate Turkey’s general economic outlook? While the economic crisis in the Eurozone continues, Turkey looks more positive. However, there is also some negative data. What developments do you expect in the economy in the coming period?

I think that Turkey’s general economic situation will move in close connection with the world economy. In recent years, the Turkish economy has been minimally affected by the world crisis. Nowadays, it is not possible to evaluate country economies only in an inward-looking manner. Countries are inevitably affected by the state of their economies, especially those with high trade volumes, and the effects of the general financial situation on exchange rates. I believe that we will feel the positive effects of Turkey’s efforts in the economic field in the coming period, but how sufficient these efforts will be will also depend on the general course of the world. Unfortunately, I think we will especially feel the negative effects of the tension in the Middle East.

The Turkish maritime industry has been going through a difficult period since 2008. How do you evaluate the general situation of the sector?

Maritime felt the effects of the global crisis in our country, as well as all over the world. The effects of this crisis are still felt around the world, especially in Europe, which can be considered the main region of the maritime industry. I don’t think this situation will change much in the near future, but I expect a positive acceleration in 2014 compared to the previous period.

How long do you think the crisis will continue? What steps should be taken by shipyards, ship owners and the state to get out of the crisis?

I believe that especially entrepreneurs have learned their own lessons during such a long period of crisis. In the future, we should not repeat the mistakes of the past period. We are in an industry that needs to be evaluated in conjunction with the world. All movements in the world have an impact on us in some way. For this reason, we must take the changing world situation into consideration both when planning our investments and preparing proposals. We must analyze our customers and the needs of the markets better. We should pay more attention to marketing. We must make an effort to introduce ourselves. In order to compete with our competitors in the world, we must realize special projects with high added value, and succeed in being the party that develops and sells technology, rather than just following it. What I expect from the government is that it will push the button to realize the projects that are especially necessary for public needs without delay. Increasing public tenders as much as possible in these crisis periods will both keep the market alive and enable public companies to meet their needs at affordable costs.

In the globalizing world, we see that the importance of institutionalization and effective marketing methods in world markets is increasing. What can be done to better promote Turkish maritime at home and abroad?

There has been a huge breakthrough in shipbuilding compared to the past regarding promotion. While one or two shipyards did not take part in the promotion in the past, I am currently observing the intense participation of Turkish shipyards in world fairs. This is a good step, but it is not enough on its own. Shipyards need to fight against themselves, especially in terms of marketing. If you do not improve yourself in marketing, your chances of getting a share of the market will become difficult because there are many competitors, so the bread is going towards the lion’s stomach, and this must be prevented. Marketing should be made one of the company’s basic strategies and main goals, but marketing power alone will be effective to some extent because shipyard is a sector where the quality of the product is expected to be high as well as marketing. We need to support marketing with the quality of our production and customer satisfaction, especially with delivery conditions, quality and time. Unless these occur, marketing alone will not be effective.

It is said that shipyards in Turkey are small in terms of area and capacity. What are your thoughts on this subject?

When we look at the shipyards in the world, our shipyards may seem small, but our area of expertise is not large vessels. First of all, we need to look at which category we are in. As everywhere else, it is necessary to specialize in a subject first. Large vessels are not feasible for our shipyards. We must continue the construction of small tonnage vessels.

In your opinion, which vessel type should shipyards in Turkey specialize in?

We carry out work on military vessels in Turkey, in terms of quality that is on par or even above Europe. We are very good at not only military vessels but also all vessels up to 20 thousand tons.

Do you think there are enough design companies actively designing vessels in Turkey?

Design is a very important issue in shipbuilding and the lack of sufficient design companies in our country is an important problem. Actually, we have good design companies, but they are not enough. If you don’t produce designs, shipbuilding will go nowhere. Anyone can build a vessel, but you have to produce the project first. Unfortunately, R&D studies are not carried out much in our country. This requires financial strength. Unfortunately, there is not much support in this sense. If chambers and associations increase their support and work a little more, the number of design companies may increase. Vessel projects currently being carried out in Turkey are similar to each other. There is no one doing R&D or producing new, original projects.

Do you think the shipbuilding industry feeds the sub-industry sufficiently?

What we call sub-industry in the vessel industry is actually the main industry. The main industry is the companies that produce the vessel’s main engine, pump and navigation system. And unfortunately, we are almost never here. We buy them from outside and assemble them here. There are companies that produce products, they produce well, but they are few and not sufficient. First of all, this problem must be solved. As GESAD, we established the Vessel Specialized Organized Industrial Zone in Yalova Çiftlikköy about 3 years ago. This is a first in Turkey. From here, we can make our vessel industry stronger by establishing partnerships with companies that are good in the sub-industry, such as Korea. We even aim to have foreign companies establish factories here. Vessels are no longer built in Europe, they produce what we call sub-industry, and they outsource the vessel to countries like us, like China.

You are also the second president of the Vessel Industrialists Association. What is on GESAD’s agenda?

GESAD is a member of the European Vessel Manufacturers Association. We are trying to provide benefits and bring projects to our members by using our relationships here. We organize meetings to strengthen relations between sectors and universities. We established the Vessel Specialized Organized Industrial Zone in Yalova. We are working to improve it. The OIZ we established in Yalova is a cluster project. We carried out the first cluster project in Turkey, we went and explained this project in Korea, they acted before us and implemented a cluster project. We are still dealing with the procedures.

The ‘Largest Passenger Vessels’ Built in the World

According to the production plan, one of the vessels to be completed every three months will be put into service. The new vessels are produced with carbon composite material used in defence, aviation and space technology, and with this feature, they are the ‘largest passenger vessels’ built in the world.

While the ferries, with a capacity of 426 people, are designed to be 39 meters long, 11.6 meters wide and at speeds that can reach 32 knots, the technology used is built with meticulous consideration for comfort and the easy use of disabled citizens.

‘Vacuum infusion’ technology used in ferries built entirely from carbon is used by a few countries and manufacturers in the world. The carbon composite construction that forms the main body of the ferry, which holds the title of being the largest passenger ferry in its class, is lighter and more durable than steel construction and consumes much less fuel due to less machine power required to passenger at the desired speed. Ferries, which are described as environmentally friendly vessels with these features, are built with passenger comfort at the forefront.