Özdemir Ataseven who is Chairman of the Board of Directors of ÖZATA Shipyard, which built the new passenger vessels of Izmir Metropolitan Municipality, said that the vessels made with carbon composite material used in aviation and space technology are the center of attention in the world maritime industry. Ataseven, who is also the Vice President of the Vessel Industrialists Association, said: “They follow our production process from all over Europe and America. Izmir will make history in the world maritime industry with this investment. You quit aluminum, you quit sheet metal, and you switch to carbon composite material. This is a breakthrough. “European banks, which have stopped lending to the sector since 2008, did not come in vain,” he said.

Ataseven continued: “This vessel which we made from carbon composite material, is 8 times lighter than normal steel weight. I am currently building a 50 meter ship of 450 tons for another customer. The vessel we built for the Metropolitan is 110 tons. Think about the fuel savings here. There is a power of pushing 450 tons, there is a power of pushing 110 tons. Repair and maintenance are also very easy. “Thank you very much from the mayor for maritime,” he said.

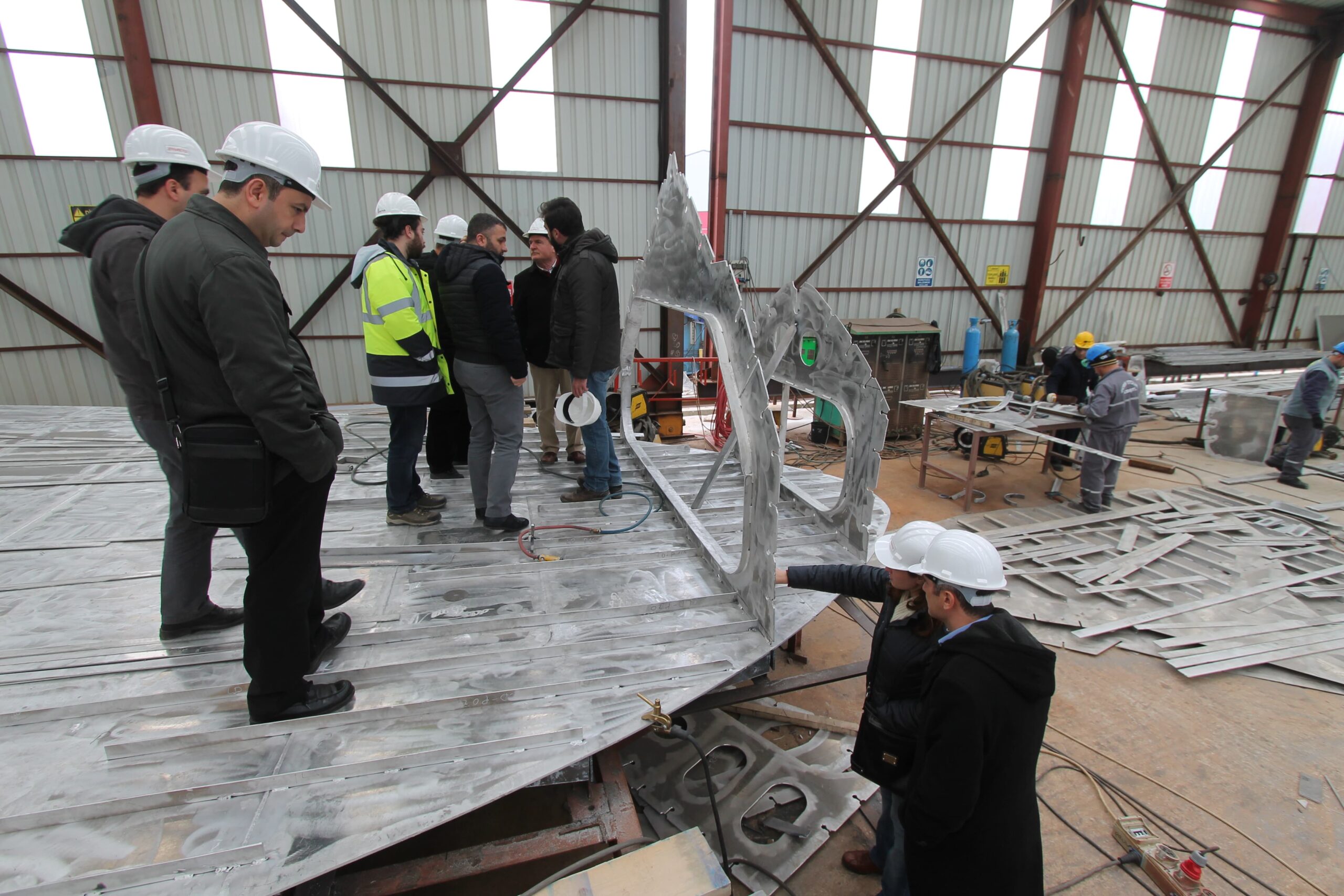

The 15 new passenger vessels to be produced with “carbon composite” material, ordered by Izmir Metropolitan Municipality in order to improve maritime transportation in the city, suddenly turned the eyes of the whole world towards Izmir. It was reported that Izmir’s new ships are the largest passenger vessels in the world to be built with carbon composite material used in aviation and space technology. Özdemir Ataseven, Chairman of the Board of Directors of ÖZATA Shipyard, which undertakes the construction of the vessels, said that Izmir Metropolitan Municipality will make history in the world maritime industry with this investment. Stating that he has been a shipbuilder for 38 years and has also been a manager in professional chambers in the sector, Ataseven said, “I am not saying that Izmir Metropolitan Municipality took the initiative in this matter. It broke new ground. This is moving from one segment to another segment. So you drop aluminum, you drop sheet metal, and you switch to carbon composite material. There is no carbon ship of this size produced in the world. We are currently building the largest vessel in our shipyard in Yalova, including the Scandinavian countries. “This is a breakthrough,” he said.

Congratulating Izmir Metropolitan Municipality Mayor Aziz Kocaoğlu for his choice of material, Ataseven said, “I really congratulate the Mayor and his team. It is very important to discover this. “I am a shipyard operator, I am involved in every management of maritime, but I have not discovered it before,” he said.

Bankers had stopped the loan

Özdemir Ataseven who is reminded that Izmir Metropolitan Municipality Mayor Aziz Kocaoğlu did a great job on behalf of the Turkish maritime sector with this investment, and 4 Development Banks from different countries of the world came together for the first time in Turkey for Izmir Metropolitan Municipality and signed a finance contract of 110.8 million Euros. He continued as follows:

“I say this not only as a shipyard but also as a manager in maritime. Currently, President Aziz Kocaoğlu is actually doing a great thing for maritime. I say only history will write this. I talked to the bank officials who came for the loan agreement. Loan to maritime industry has stopped since 2008. Nobody was giving loans to maritime. But look how many banks came and are giving loans to this project. They don’t come in vain. So, when I return to my shipyard, all the banks will come. They will start to look favorably on other sailors. Most importantly, carbon material has added a lot. In my opinion, coastal municipalities and the state will have it done this way from now on. It’s impossible not to have it done anyway. If he doesn’t get it done, they will hold him accountable.”

There is nothing like it!

Özdemir Ataseven, who is also the Vice President of the Ship Industrialists Association, underlined that the world’s eyes are on them because these ships they produce for Izmir are special in terms of size and material, and said, “Since we are currently purchasing carbon and materials, many companies, including from America, is coming to us. We know that they follow our production process from all over Europe and America. Here’s why: Scandinavians do this; Other European countries also want to enter, but the price seems high. Because for them, worker hour is 53 Euros, for us it is 13 Euros. Now, when they see the prices we make, everyone in the sea will return to this ship, that is, carbon. But it is not possible for them to build this ship in such large quantities. Because their shipyards are not located that way. “The infrastructure we have prepared for the Izmir Metropolitan Municipality ships is currently unique in Europe,” he said.

These Vessels ‘’100 Percentage of Environmentally Friendly’’

Ataseven said that the ship production work was going as planned and that this project excited him very much, and that the new vessels are “100 percent environmentally friendly and marine” and that as a passenger ship, nothing else can be done on top of this technology. Noting that the new fleet they prepared for Izmir Metropolitan Municipality in their shipyard in Yalova will provide fuel savings of over 50 percent, Ataseven said, “This vessel, which we made from carbon composite material, will be around 100-110 tons. But the main engine inside is the same as I put in other ships. When you look at others, it is 8 times lighter than normal steel weight. I am currently building a 50 meter ship of 450 tons for another customer. The ship we built for the Metropolitan is 110 tons. Think about the fuel savings here. There is a power of pushing 450 tons, there is a power of pushing 110 tons. This material is very important for maritime. Due to this great reduction in fuel consumption, ships built with carbon composite technology pay for themselves in a short time. Repair and maintenance are also very easy. “I am thankfull for maritime,” he said.

The Whole World is Following Us

Stating that 15 carbon composite passenger vesels of this size and within the scope of a single tender were built for the first time in the world, Ataseven said, “Let me say this first. There is nothing of this size in the world anyway. There are also some pieces made piecemeal in Turkey. But there is no fully infused, full carbon boat,” he said.

Reminding that large companies that provide service with passenger vessels have to choose ships that are fuel efficient, Özdemir Ataseven said, “Because there are people who use them as shuttle services and they have to have them built in large numbers. They are currently waiting because they find the price high. But now, when our prices drop, things will change. All companies, I’m not just talking about Türkiye, the whole world are following us. Because these services are available everywhere where oil is produced,” he said.

Underlining that wind energy is produced by placing pontoons in the sea, Ataseven said, “There will be a huge demand for these ships to serve them. In my opinion, there will be completely carbon composite ships at sea from now on. “Everyone will change their demands in a short time,” he said.